With the decarbonisation of transport comes greater demand for electric vehicles and by extension, rare elements that form their motors and batteries. Up to 80% more copper is used in an electric vehicle compared to a traditional combustion engine to give just one example. Copper, along with lithium, cobalt, aluminium and Rare Earth Elements are crucial in the makeup of electric vehicles and many of these elements already deemed as being in critical supply. In this article, I will explore the fate of these already sparse materials with a view to how we can ensure that metals are extracted and used economically and ethically.

Copper has many properties which make it useful and it is a commonplace material in modern society; it’s an essential part in practically all wiring systems due to its conductivity, it’s used for rooves and in guttering because of its durability, and humans need about 1.2 milligrams of copper per day to help enzymes in the body transfer energy between cells. However, although it is commonplace, copper is actually a rarity in the earth’s surface (aka the crust), forming just 27 parts per million. This means for every kilogram of soil, just 27 milligrams of copper is found. For context, this compares to aluminium at 84,149 parts per million and the precious metal gold at just 0.001 parts per million. A similar story is seen across metals such as cobalt and lithium.

Copper and aluminium are used in large amounts in an electric vehicle’s (EV) body, motor and battery. In fact, analysis by the UBS Evidence Lab shows that a Chevy Bolt, the world’s first mass-market electric vehicle, contains 80% more copper and 70% more aluminium than a traditional-fuel Volkswagen Golf.

Perhaps more concerning than this is the amount of cobalt, a metal found in the Earth’s crust at just 30 parts per million, used in renewable technologies and EVs. Cobalt along with lithium is also used for the manufacture of lithium-ion batteries which are common in smartphones as well as EV batteries. These metals were placed at a 7.6 and 8.1 level of risk in the British Goelogical Survey’s 2015 element risk list which gives an indication of the risk of supply based on location of current production and reserves, and the political stability of those locations.

Not surprisingly, elements which form the Rare Earth Element (REE) group were at the top of the risk list in 2015 due to their scarcity. The extraction and supply of REEs is dominated by China where there is an abundance of these deposits, so this trend is likely to continue. REEs are found in huge amounts in EVs, reaching a staggering total weight of 1kg in a single EV. Therefore, increases in the number of EVs on roads globally is very likely to have a massive impact on the availability of these critical metals.

So much so, it has been predicted by the UBS Evidence Lab that in the future mobility realm, entirely composed of electric vehicles, the demand for the following elements will be increased:

- Lithium (+2511%)

- Cobalt (+1928%)

- Rare Earth Elements (+100%)

- Copper (+21%)

- Aluminium (+12%)

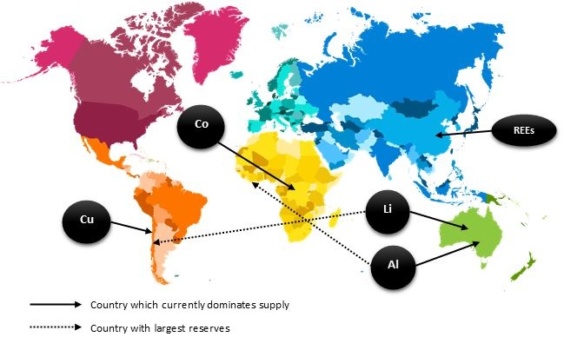

The security of supply of these metals, particularly as specific countries currently dominate the market in terms of the availability and extraction supply chain, could be concerning for those in the battery and EV manufacture industry. For example, the graphic below shows that at the moment China dominates supply of REEs, the Democratic Republic of Congo dominates for cobalt and Chile for copper. The leading producer of lithium and aluminium today is Australia which is world-renowned in terms of precious metal and opal production but presents particular problems in terms of creating a low-carbon supply chain to Europe with carbon-heavy shipping and air freight offering the main options for resource transport. However, the British Geological Survey suggest that the top reserves are actually found in Chile and Guinea respectively. This poses a question for the security of supply of these elements in the future and indicates that supply chains and investment will differ greatly in years to come. Increased reliance on critical metals and materials as batteries and EVs become more common will also rely on the geopolitics of supply chains and international political developments.

However, there may be a simple solution to ensuring that critical metals do not become over-extracted. Implementation of principles surrounding resource efficiency and the circular economy could help ensure that each minuscule of metal is used as much as possible before it is made redundant. There has been significant research into circular economy principles for metals and mining in recent years, with the International Council on Metals and Mining highlighting that “metals are infinitely recyclable.”

The circular economy principles are likely to become crucial to the supply of high-value critical metals in years to come and there should be organisation-specific frameworks for ensuring resource efficiency and that a circular economy is achieved. This will not only save the organisation itself costs and hassle associated with securing a stable supply of metals but will also help to ensure that there are sustainable metal supply chains for future generations to utilize whilst minimising the environmental effects of metal extraction by reducing demand.

The changing future of mobility will almost certainly cause widespread changes in supply chains across the globe. For EVs and critical metals such as copper, cobalt, lithium and the REEs within the EVs, this may mean step changes in the rate and location of supply to meet increased demand. It is more important than ever to ensure every resource is used to the maximum before being discarded and implementation of the circular economy as well as resource efficiency and the processing of wastes to make useful products can help achieve this.

For more information on this blog or the principles within, please contact Christina Thompson-Yates at christina.thompson-yates@gemserv.com.